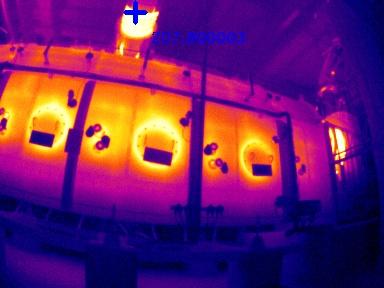

AI Intelligent Video Analysis

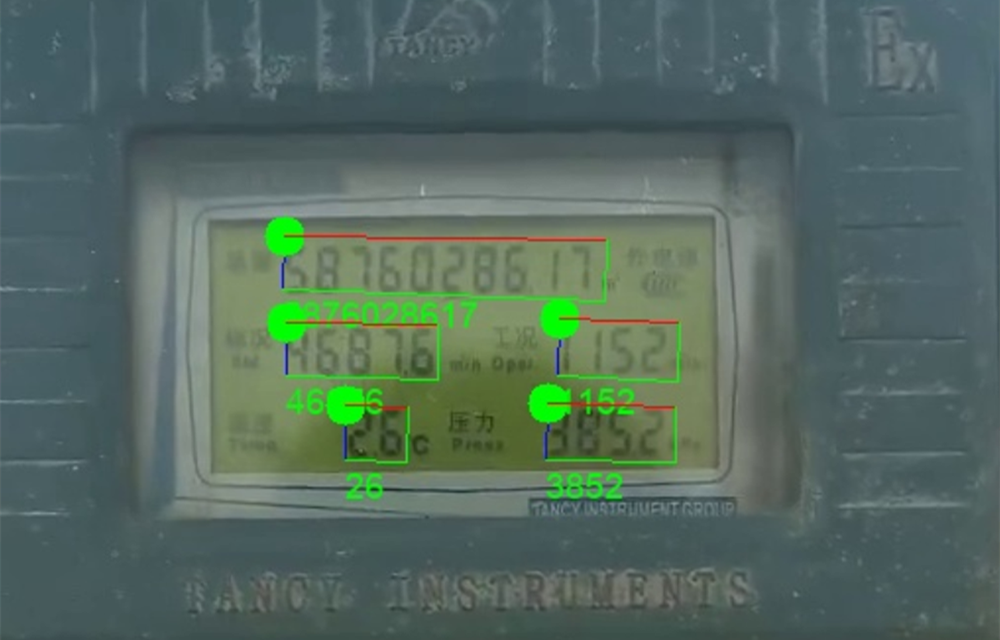

- A self-developed deep learning image algorithm development platform.

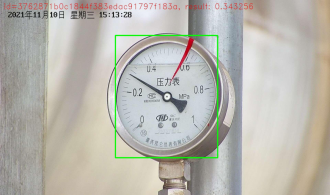

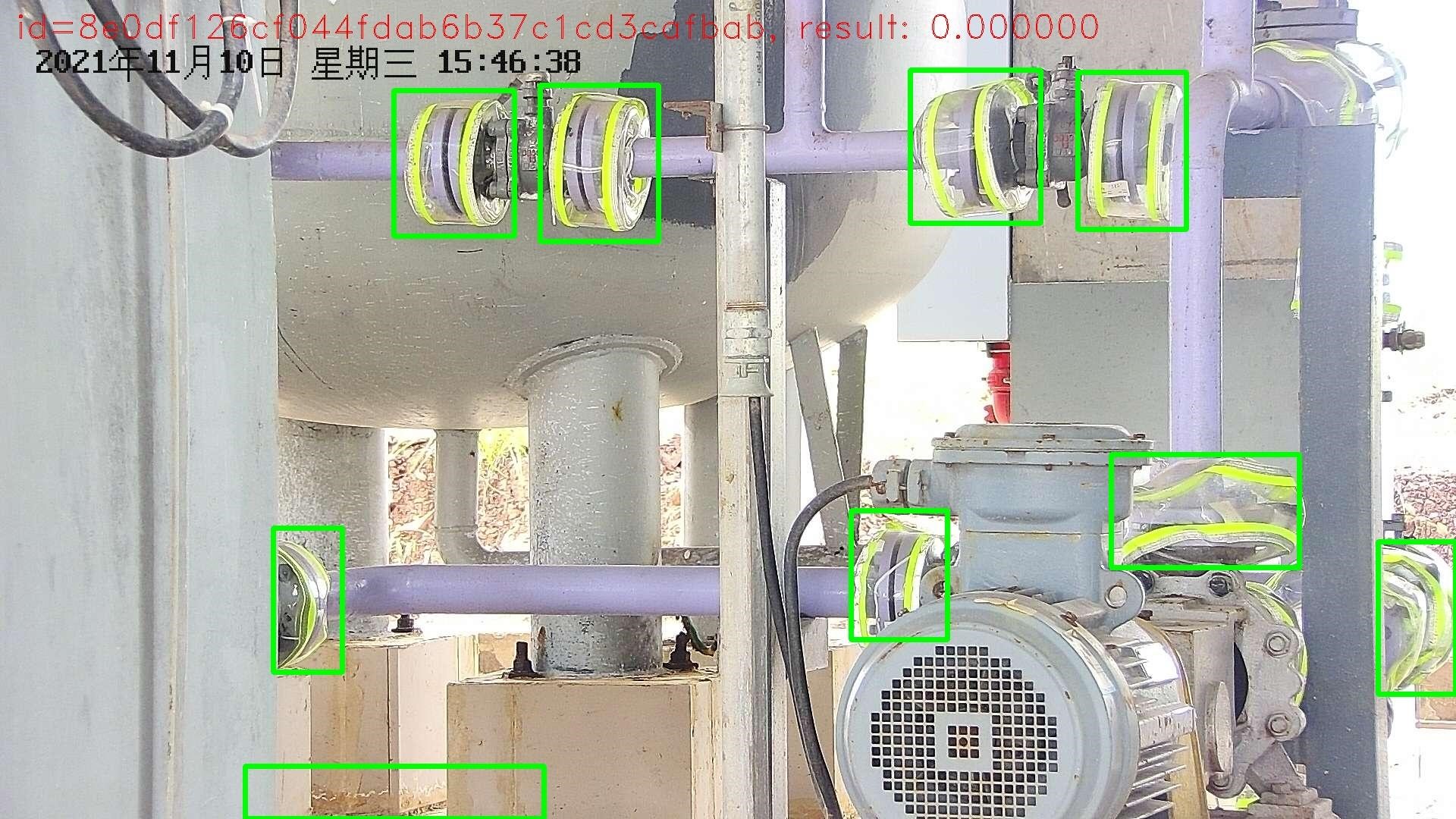

- Real time video access analysis, second level warning, intelligent control.

- Fully utilize existing video surveillance resources.

- Intelligent robots combined with fixed point monitoring to achieve blind spot safety monitoring.